Fixing-kit with wedge for Conti Polyrope®

Flat belt CONTI POLYROPE® must be applied together with a normalized fixing-kit.

The end connections of the Polyrope shall be self tightening wedge type sockets , they shall be made of metallic material and shall resist 80% of the minimum breaking load of the Polyrope, the angle of the housing and wedge shall be equal and in between 20° and 25°. Other types of end connectors are allowed only after a written declaration is received that will function as an extension to this certificate.

Standaretized wedge socket and a elevator fixing-kit with three flat belts 25-6x2,0

Instruction, installation and examination manual for the fixing-kit Polyrope

CONTI POLYROPE Certificate according Lift Directive 95/16/EC - preview (581kb)

Traction and deflection pulleys

Flat belt CONTI POLYROPE® shall be applied in combination with a dedicated traction pulley with semicircular grooves. For POLYROPE with flat backside, deflection pulleys may have either the same grooves as the traction sheave in case of twisted application, or a convex shape (crowned) for alingment and a rim to protect against extreme sideward movementrs, in case the flat side is used as running surface.

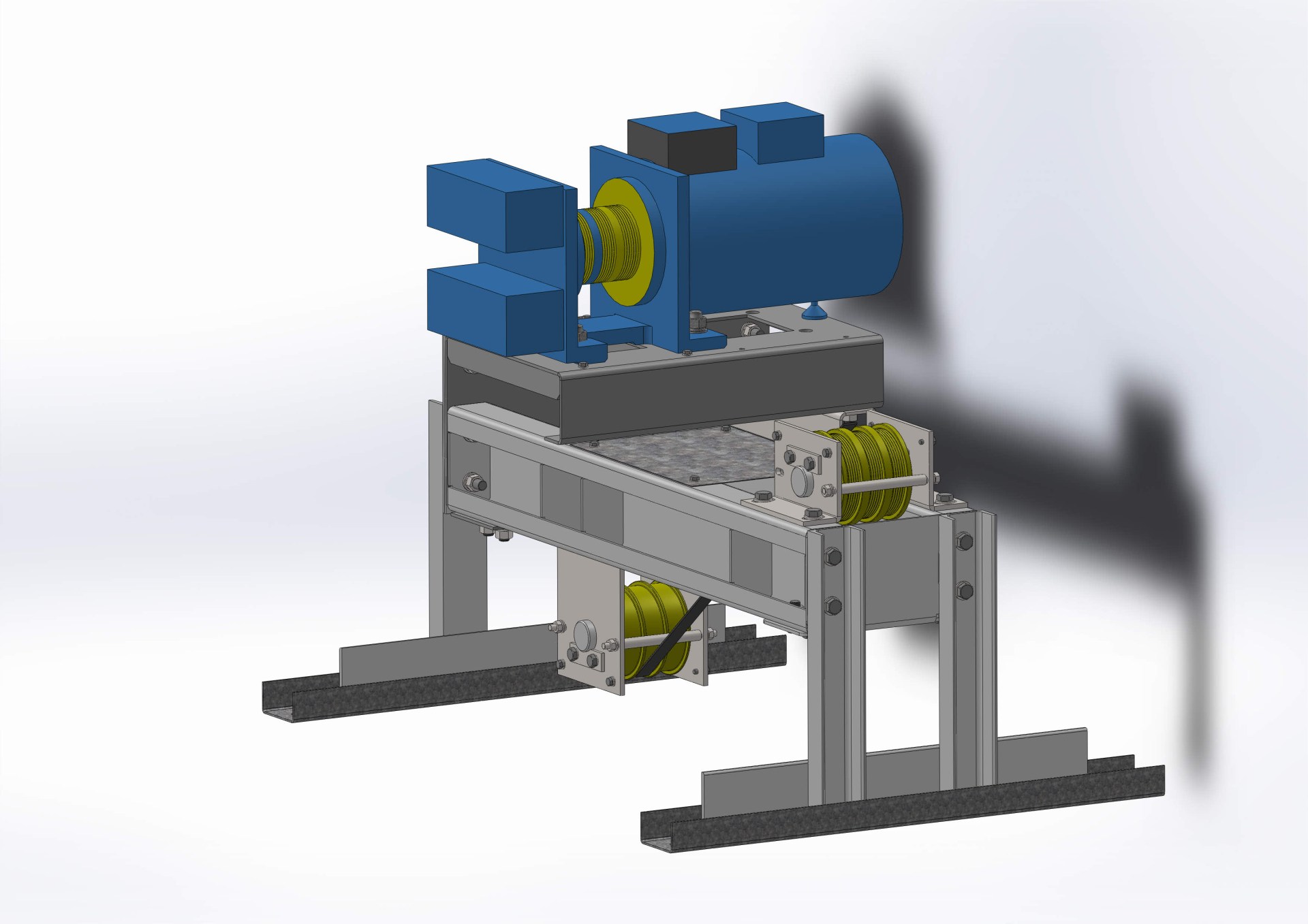

Frame of the lift machine with a traction and deflection pulleys.

Example of a grooved and a flat deflection pulley with a bearing - material plastic PA

| Main data of traction pulley | |

| Effective pulley diameter | > 100 mm (centre - centre of rope). |

| Groove shape | semicircular radius 1,9 mm. |

| Groove material | Steel preferably 42CrMo4 |

| Groove surface | Hardened to 55-62 HRC or CrNi hard surface coating; Roughness Ra 1,6 - 3,2 μm. |

| Main data of deflection pulley | |

| Pulley diameter | > 100 mm |

| Pulley shape | Covex radius 500 mm (running over flat side) or grooved identical to traction pulley (running over grooved side). |

| Pulley material | Steel preferably 42CrMo4 or PA |

| Pulley surface | Roughness Ra max. 5 μm, preferably with low friction properties. |